|

Plastics: CNC custom machining and prototyping

AC Manufacturing is a complete cnc machine shop capable of machining parts to customer specification (conventional and 5 axis machining). We can machine to print and accept the most common file formats including:

.dwg .dxf .iges .step .sat as well as .pdf files. If you don't see your file format here let us know.

Please send us files to: sales@acmanufacturing.com

We can accept both small and large run jobs of custom machined parts.

We provide Turning and Milling, 3 axis , 3+2 axis & continuous 5 axis machining).

We accept both small and large run jobs, Minimum quantity for order is 1.

Short lead times are often available 2-3 days.

Standard lead time is 2 weeks.

We machine many common kinds of plastics and substrates: ABS, Acetal, Acrylic, Cirlex, Delmat, Delrin, Durastone, Formex, G-9, G-10, G-11, GPO3, Kapton, Lexan, Nomex, Nylon, Phenolic, Polycarbonate, Polyester, Polypropylene, Polystyrene, Polysulfone, PVC, Ryton, Torlon, Ultem, Urethane, Valox, Vespel, Vinyl. Have a look and check out how we use 5 axis machines to manufacture

plastics part out of peek ceramic material.

Plastics are organic polymers of high molecular mass, usually synthetic, most commonly derived from petrochemicals, but many are made from renewable materials such as polylactic acid from corn or cellulosics from cotton linters. Plasticity is the general property of all materials that are able to irreversibly deform without breaking.

Plastics are organic polymers of high molecular mass, usually synthetic, most commonly derived from petrochemicals, but many are made from renewable materials such as polylactic acid from corn or cellulosics from cotton linters. Plasticity is the general property of all materials that are able to irreversibly deform without breaking.

Why use and machine plastics? One of main resons is the rising costs of metal. This leads many to seek ways to replace machined metal parts with plastics. As a result, cnc job shops are seeing an increase in requests for plastic parts by their customers.

Most quality stock shape materials are stress relieved to ensure the highest degree of machinability and dimensional stability.

However, the relative softness of plastics (compared to metals) generally results in greater difficulty for maintaining tight tolerances during and after machining. A good rule of thumb for tolerances of plastic parts is +/- .001 per inch of dimension although tighter tolerances are possible with very stable, reinforced materials.

Most quality stock shape materials are stress relieved to ensure the highest degree of machinability and dimensional stability.

However, the relative softness of plastics (compared to metals) generally results in greater difficulty for maintaining tight tolerances during and after machining. A good rule of thumb for tolerances of plastic parts is +/- .001 per inch of dimension although tighter tolerances are possible with very stable, reinforced materials.

Quality quick turn plastics machining with Competitive Pricing. Privately owned and housed in a modern state of the art facility, AC Manufacturing has the flexibility to provide competitively-priced precision CNC plastic machining services. You can rely on AC Manufacturing from conceptualization, through the protyping process, small custom products runs to large volume runs to provide a seamless experience.

Machining plastics

Plastic machining has many advantages worth considering: greatest design change flexibility,

Greatest cost efficiency for smaller quantities, no parting lines, ejector marks, or flash, no draft angles required, closest tolerances possible, lowest component stress, fastest turnaround time

, low or no tooling cost, ease of producing features such as threads and undercuts.

While the switch from metal to plastic machining doesnít require a new equipment purchase, it may require new ways of thinking and working. Thatís because plastics machine differently than metal, differently from one plastic to another, differently from lot to lot and from section to section (due to material inconsistency).

Machinists have to adapt quickly to challenges and this is a necessity because many of these plastic parts are produced in small runs and problems must be worked out quickly. The more you work with machining plastics the faster you get at solving problems and picking up the tricks of the trade.We use 5 axis machines such as Haas UMC 750 and Haas VF-5SS as well as conventional milling equipment (Matsuura RA-1G, MC 500V PC 2S and MC-510 VG)

Machinists have to adapt quickly to challenges and this is a necessity because many of these plastic parts are produced in small runs and problems must be worked out quickly. The more you work with machining plastics the faster you get at solving problems and picking up the tricks of the trade.We use 5 axis machines such as Haas UMC 750 and Haas VF-5SS as well as conventional milling equipment (Matsuura RA-1G, MC 500V PC 2S and MC-510 VG)

It is worth to remember that thermal expansion of plastics is up to 10 times greater with plastics than metals,

plastics lose heat more slowly than metals, so localized overheating has to be avoided and softening (and melting) temperatures of plastics are much lower than metals.

Coolants are generally not required for most plastic machining operations (not including drilling and parting off). However, for optimum surface finishes and close tolerances, non-aromatic, water soluble coolants are recommended.

It is worth to remember that thermal expansion of plastics is up to 10 times greater with plastics than metals,

plastics lose heat more slowly than metals, so localized overheating has to be avoided and softening (and melting) temperatures of plastics are much lower than metals.

Coolants are generally not required for most plastic machining operations (not including drilling and parting off). However, for optimum surface finishes and close tolerances, non-aromatic, water soluble coolants are recommended.

Compared to machining steel parts, when machining plastics parts, the RPM can be lower and the feed faster. This way the spindle

speed isnít causing too much friction and the high feeds donít allow the tool to stay in one area long enough for any heat present to melt the plastic. Another consideration is that if the RPM is too high, heated chips of molten plastic can fling out and melt to the surface of a perfectly good part.

Some machining tips to know:

- Rip and combination blades with a 0° tooth rake and 3° to 10° tooth set are best for general sawing in order to reduce frictional heat.

- Hollow ground circular saw blades without set will yield smooth cuts up to 3/4” thickness.

- RPM can be lower and the feed faster

- Tungsten carbide blades wear well and provide optimize surface finishes.

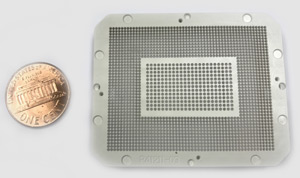

Ceramic-filled Peek

PEEK with ceramic fillers to significantly improve its mechanical properties: excellent dimensional stability, good impact strength, stiffness an minimum levels of creep, better impact resistance and toughness

compared with ceramics. Excellent machinability for tighter pitch

and fine diameter holes.

There is an wide selection of plastics to choose from: highly engineered, high performance products to low cost, low performance. Determining which is appropriate for a particular application can be challenging. Many plastics are available with fillers to enhance particular characteristics. For example, glass fill improves tensile strength while reducing machinability. Molybdenum disulphide improves wear while reducing dimensional stability. |